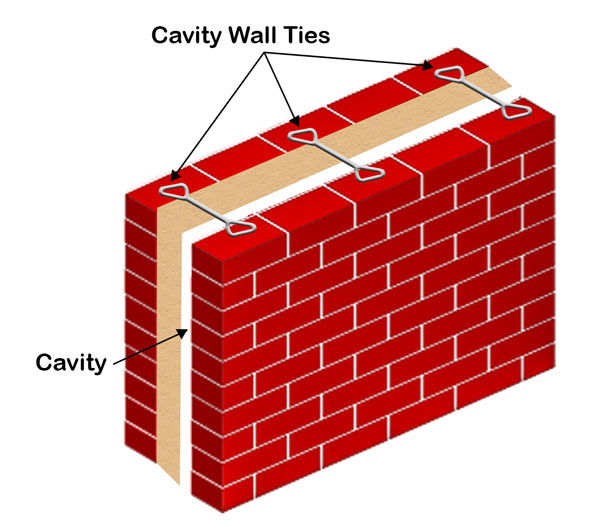

A cavity wall is a dual-layer masonry system separated by an air gap, improving insulation and resisting moisture. The outer and inner leaves are tied with metal or plastic wall ties, while weep holes and flashing help drain water out of the structure.

Benefits of Cavity Walls

Thermal performance is one of the main reasons developers choose cavity walls. Homes in hot regions stay cooler longer, while those in colder zones retain warmth—reducing reliance on artificial climate control.

In areas where affordable plots are being developed, builders prefer cavity walls due to long-term cost efficiency and energy savings. This method balances performance and affordability better than many traditional solid-wall builds.

Moisture resistance is another critical advantage. With proper flashing and open weep holes, cavity walls stop rainwater from reaching internal finishes, preventing damp-related issues that can affect resale value—something that matters greatly when flipping renovated homes.

Soundproofing is another strong suit. In high-traffic areas, cavity wall structures drastically cut noise intrusion.

Common Construction Materials

- Outer Leaf: Typically decorative stone or face brick

- Inner Leaf: Concrete blocks or structural brick

- Insulation: Mineral wool, rigid foam boards

- Wall Ties: Galvanized steel or polymer

- Flashings & DPC: Moisture barriers

- Weep Holes: Water egress points

In building projects across Kenya, these materials are sourced locally and adapted to climate needs.

Step-by-Step Process

- Lay the foundation with a proper damp-proof course

- Build the inner leaf using reinforced blocks

- Insert wall ties and insulation board layer

- Construct the outer masonry leaf

- Install flashing above doors/windows

- Leave weep holes at the base

- Finish with plaster/render as required

This system is common in suburbs like Utawala, where housing developments focus on structural strength and cost-efficiency.

Cavity Wall vs Other Wall Types

| Wall Type | Insulation | Moisture Resistance | Cost |

|---|---|---|---|

| Cavity Wall | Excellent | Excellent | Moderate–High |

| Solid Masonry | Poor | Poor | Low |

| Rammed Earth | High | Medium | Medium |

| SIP Panels | Excellent | Excellent | High |

In newer neighborhoods promoting affordable housing, cavity walls offer long-term gains by lowering maintenance costs and utility bills.

Avoidable Mistakes

- Omitting insulation or using incorrect board thickness

- Skipping flashing or misplacing weep holes

- Using low-quality wall ties that corrode

- Blocking the cavity during construction

- Misaligning inner and outer leaves

Real-World Applications

In Nairobi’s construction city, areas like Syokimau and Thika Road are seeing widespread adoption of cavity walls in both apartments and standalone units. Their energy savings and low maintenance also make them popular when restoring abandoned houses for sale.

Cost Breakdown

- Bricks or blocks: Ksh 80–150 per unit

- Insulation: Ksh 1,500–2,500 per m²

- Labor: Ksh 300–600 per m²

- Wall ties/flashing: Ksh 20–40 per m

That translates to Ksh 6,500–12,000 per m², depending on specs. Compared to cheaper houses for sale in Kenya, cavity wall homes cost more to build but offer far better performance and durability.

Final Thoughts

Cavity walls provide excellent insulation, long-term durability, fire resistance, and sound control—making them ideal for both new developments and renovated homes being flipped for profit.

They are also a key feature in the evolution of affordable housing across Kenya, where smarter materials and design lead to smarter investments.